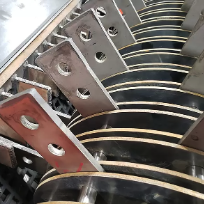

In the realm of industrial grinding solutions, Schutte Hammermill has long been a trusted name, renowned for its innovative machinery and commitment to customer satisfaction. Now, with great excitement, we’re proud to announce the launch of our redesigned website, hammermills.com, featuring a new user-friendly navigation, enhanced accessibility, and streamlined communication. Our primary objective with this… Read more »